Case Studies

Revolutionizing Wood Manufacturing: Robotics Integration for Saw Feeding Operations

In Montana, wood manufacturing is a prevalent industry among small-scale manufacturers. However, the repetitive and monotonous task of feeding boards into saws posed a significant challenge, as finding employees willing to undertake this labor-intensive job was difficult. To address this issue and enhance operational efficiency, robotics integration emerged as a transformative solution, enabling manufacturers to automate saw feeding tasks and optimize workforce utilization.

Transforming Packaging Operations: Robotics Integration for Worker Safety and Efficiency

This case study highlights the successful integration of robotics technology at a manufacturing facility to address the challenges of heavy manual labor and workforce shortages in the packaging department. By leveraging robotics, the company not only enhanced worker safety but also optimized operational efficiency and productivity.

Modernizing Pool Operations: Automation at a Hot Springs Resort

This case study delves into the unexpected application of automation technology at a hot springs resort, where the complex nature of pool operations and the limitations of seasonal, part-time staff necessitated innovative solutions.

Streamlining Manufacturing Processes: Automation of Hydraulic Presses in a Factory Setting

In the realm of manufacturing, efficiency is paramount. Yet, many factories grapple with outdated equipment and manual processes that hinder productivity and quality control. This case study delves into the transformation of a factory plagued by manual hydraulic presses into a streamlined, automated operation, revolutionizing the manufacturing process and enhancing overall productivity.

MISCELLANEOUS PROJECTS

From industrial automation solutions to sustainable energy systems, Archenergy tackles a wide range of projects. Browse our image gallery to see how we’ve helped businesses optimize operations, improve efficiency, and achieve their goals. Whether you need a custom control panel, a robotic integration, or an off-grid power solution, Archenergy’s expertise can bring your vision to life.

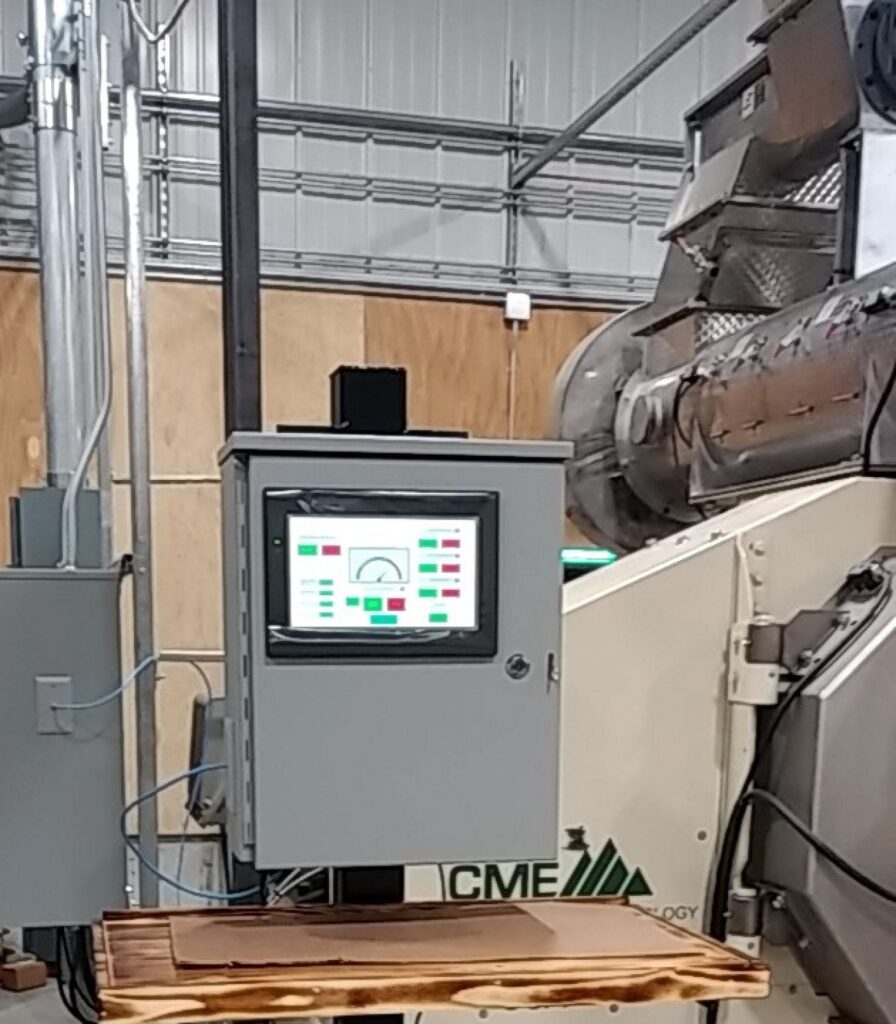

Pellet Mill

This all-of-the-above project involved electrical system design, industrial automation design and installation, PLC programming, and installation of industrial control panels and motor control equipment. The design phase incorporated calculating the electrical load for all equipment, lighting, outlets, etc within the building, calculating the size of the electrical service, feeder cables, conductor and conduit sizes, and then designing panel locations, lighting layout, outlet and switch locations.

Hybrid Solar Automation and DC Disrtibution

This is where automation meets renewable energy. Not only is this the first structure in Montana to get a solar shingle array, it is also the only known DC distribution system in Montana that has a multi-voltage DC system for 24V and 48V lighting. It includes the only known battery management system that can monitor voltage levels of each individual flooded lead acid battery within a 48V solar battery bank.