Automation

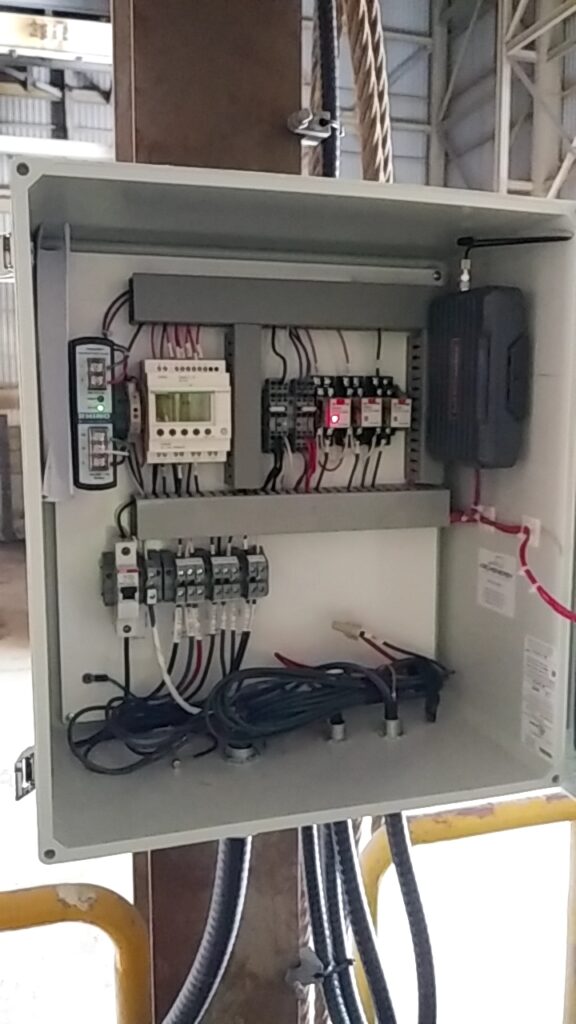

Customized PLC’s & HMI’s

Welcome to the future of manufacturing! Automation is revolutionizing the industry, offering a myriad of benefits that not only streamline processes but also enhance productivity and efficiency. Let’s delve into why automation is the game-changer you need for your factory.

One of the most compelling reasons is increased production at a lower cost. By streamlining processes and minimizing downtime, automation maximizes efficiency while minimizing operational expenses. A factory process that once relied on several operators performing mundane tasks that consumed human labor can now be streamlined to a single operator, freeing up valuable human resources that can then be focused on more critical and important tasks in your company.

Automation eliminates the risk of human error. You won’t have to worry about someone making a mistake or hurting themselves while operating your machinery. Processes are automatically executed accurately and consistently. Imagine a factory floor bustling with machines, each requiring precise monitoring and control. With automation, this complexity is simplified into one comprehensive interface that reliably and accurately executes the operation.

A computer-controlled automated process gives you access to data on your industrial functions that can be compiled and presented in any way you wish, and you can act on that data. Data points are continuously gathered at various stages of production, capturing intricate details from raw material input to final product output.

But the benefits don’t end there. Automation offers remote control capabilities, enabling you to oversee operations from anywhere in the world giving you powerful monitoring and remote control capabilities. Gone are the days of being tethered to the factory floor. Whether you’re on vacation on a serene Caribbean beach or on the other side of the world on a business trip, it’s all at your fingertips, you are still in full control of your factory’s operations. You can still monitor, control, and modify your factory back home.

The Main Components of Automation

Programmable Logic Controllers

Imagine an industrial supercomputer, programmed specifically to operate an entire manufacturing process from the ground up. It doesn’t need updates, it doesn’t need a human operator, and it can run for years, even decades without any issue. With the appropriate sensors and the wiring of machines to this computer, an entire industrial process can be automated. All a human operator needs to do is dictate what process they want carried out, and the computer will achieve that process on its own. The PLC virtually presses the start and stop buttons, pulls the levers and switches, and runs all the systems required by the industrial process without human intervention.

Human Machine Interfaces

HMI: a Human-Machine Interface. These are unique, tailor-made touchpads designed to be user-friendly and intuitive. These touch-screen interfaces empower you to closely monitor production metrics and respond swiftly to any changes in demand. Paired with PLCs, our HMI’s offer a plethora of options, a single individual can monitor and dictate every aspects of a company’s operation, Any change that needs to be made to the industrial operation can be implemented quickly and easily, with just the touch of a few buttons.

Each HMI we design is user friendly and doesn’t require any specialized training. A custom HMI in conjunction with a PLC can allow you to take full command of your company’s operations.

Why Choose Us?

When it comes to your automation needs, why settle for anything less than the best? Here at ARCHENERGY, we pride ourselves on being the top choice for businesses looking for innovative and reliable automation solutions. Here’s five reasons why you should choose us:

- Established Excellence: With years of experience under our belt, we’ve established ourselves as a trusted name in the industry. Located in the Belgrade Montana area for a significant period, we have deep roots in the community and a reputation for reliability.

- Diverse Skill-set: Our team brings a wealth of expertise to the table, encompassing electrical contracting, electrical engineering, mechanical engineering, computer science, welding, and fabrication. As a testament to our commitment to excellence, our founder holds a degree in electrical engineering, master electrician license, unlimited electrical contractor license, and an AWS welding certification.

- Innovation at its Core: We don’t just think outside the box – we redefine it. Our approach to automation is marked by creativity, innovation, and a willingness to push the boundaries. We thrive on crafting unique, custom solutions that address your specific needs and challenges.

- End-to-End Solutions: From design and build to installation and integration, we handle every aspect of the automation process. We start by evaluating your factory’s current setup, identifying choke points, and designing tailored solutions. Then, we seamlessly integrate these solutions into your existing processes, ensuring a smooth transition to enhanced efficiency and productivity.

- One-Stop Shop: We pride ourselves on being a one-stop shop for all your automation needs. Whether you need consulting, design, fabrication, installation, or ongoing support, we’ve got you covered. With us, you can streamline the entire automation process, saving time, resources, and headaches along the way.

Automation System Experts

An automation system is not something you can buy off a shelf at a store. These systems have to be uniquely designed from the ground up to meet a certain need. Each industrial process is unique. We specialize in designing and developing proprietary PLC systems that are tuned to the specific needs of your factory, whether that’s manufacturing parts or packaging product.

More importantly, these systems often require tuning and adjustment after their initial production to eke out the maximum amount of efficiency in your factory, and we are committed to carrying out those tasks as well. We don’t sell a mass-produced product that can never be the perfect fit: we build the system specifically for you from the ground up, and make every adjustment needed so it can be a perfect fit for your factory needs.